CO₂ Laser Engraving Marble tool

With its high precision and fast engraving speed , CO2 laser machine engraving on marble revolutionized the art of engraving. Marble is a timeless and elegant material that can be transformed into a canvas for personalized designs through laser engraving. It is a process that involves the use of a high-powered laser beam that is focused onto the surface of the marble, and with the help of computer software, the laser beam engraves intricate designs onto the marble surface.

Video shows:

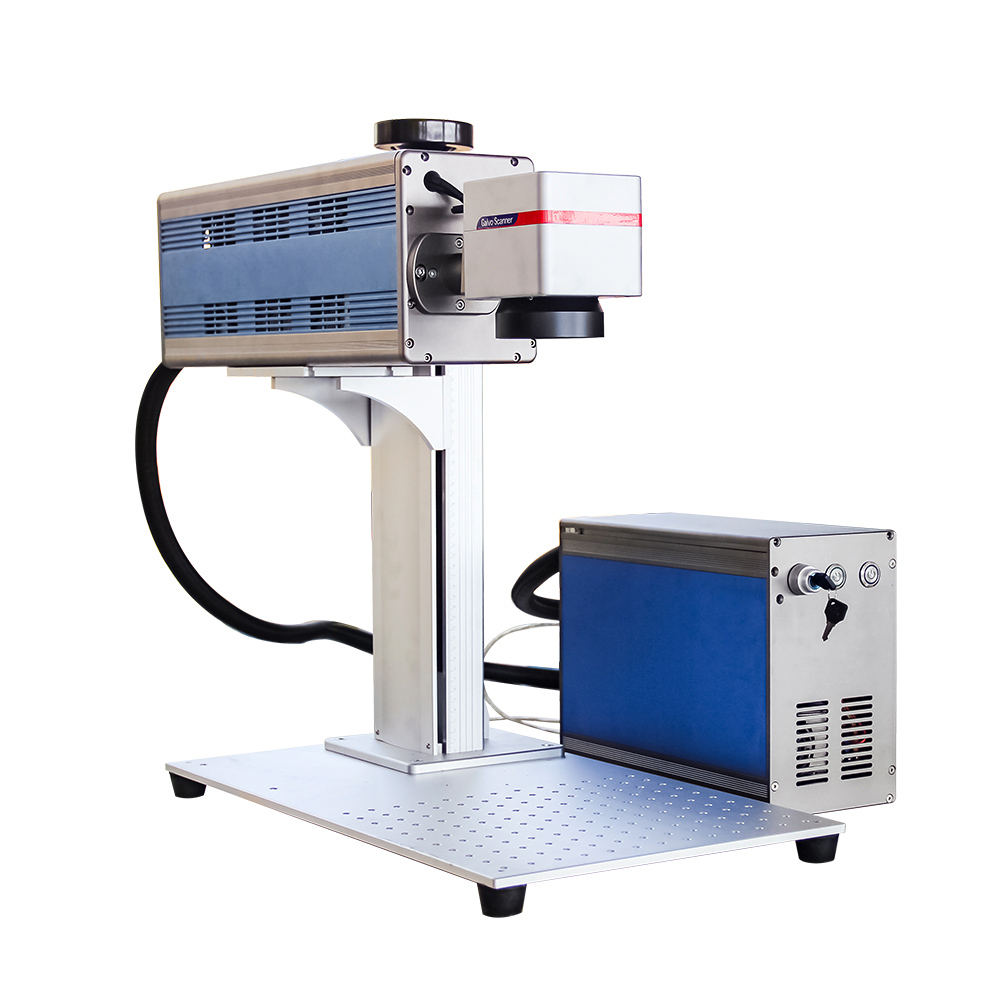

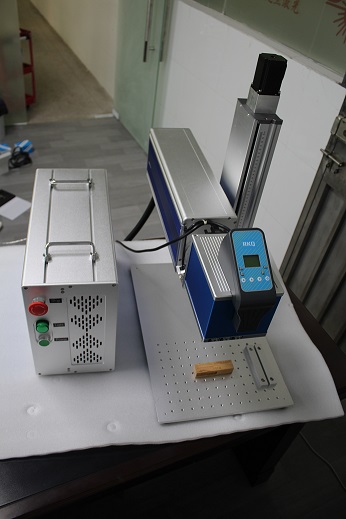

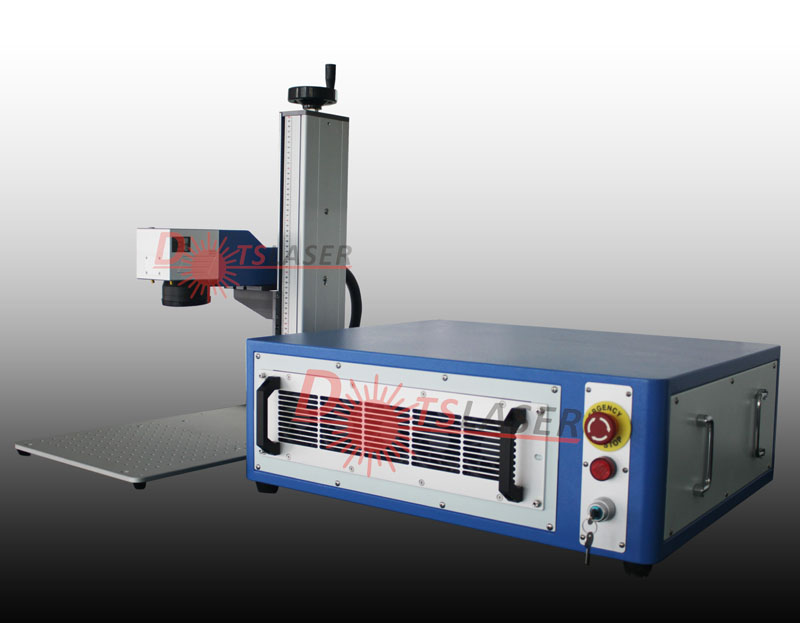

Machine features:

Portable: Convenient table, easy to move and operate, convenient for customers to use, good heat dissipation performance, anti-dust design, integration styles.

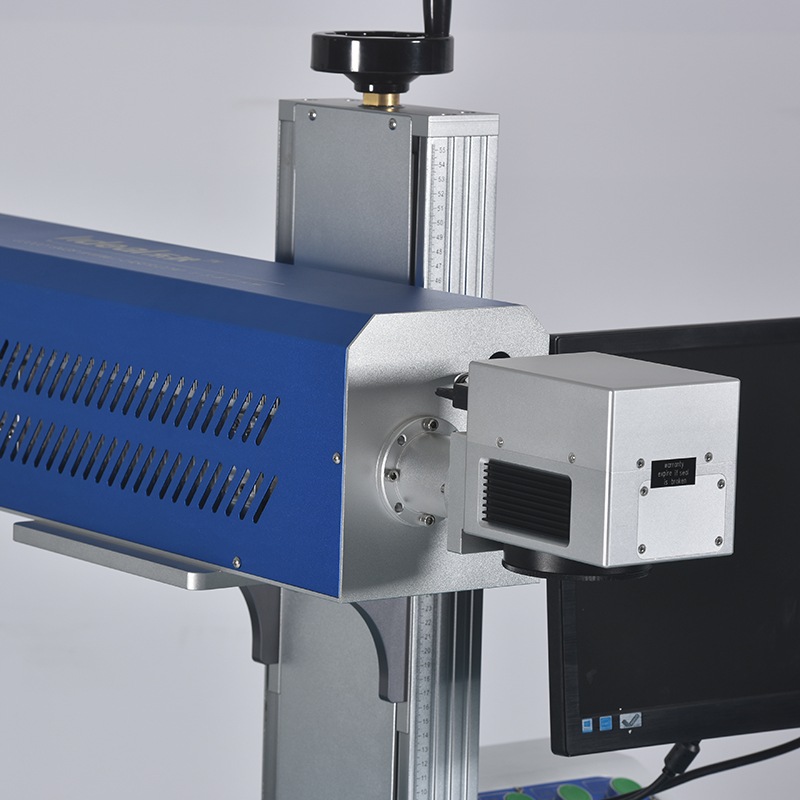

Customized control board: Control board is the "brain" of a laser engraving, a professional control board and software can give a good order to machine to proceed good work. DOTSLASER adopt processional control board and software fit for our machines perfectly. and easy to operate, no need complicated training. Many competitors use controller which is copied or pirated by unprofessional programmer. So it leads to issues such as lots of bugs, failure,disconnection, no update,copyright.

Leading laser source:It is very stable and with good laser beam output, high pulse energy, suit for long time laser processing on harden stones; Many competitors assembly unknown laser source, which is unstable and has a high failure rate, not good for long time engraving hard stones.

Leading SUPER galvo: Compared with traditional ordinary laser engraving machine, its spot size is far more fine, so it can engrave on wide area at the same laser power. or has 30%~50% more fine lines at same working area. so engrave smaller text is feasible.

Machine parameter:

NO. | Name | CO2 laser marking machine |

1 | Machine model | DS-LM60 |

2 | Rated output power | 55W/80W |

3 | laser wavelength | 10640 nm |

4 | Laser level | Class 4 |

5 | Repeat accuracy | ±0.01mm |

6 | Min.line width | 0.1mm |

7 | Min.character size | 0.5mm |

8 | Max marking speed | 8000mm/s |

9 | Working area | 100x100mm(standard)/200x200mm/300x300mm |

10 | Cooling | Air cooled |

11 | Working environment temperature range | 5~35 ℃ |

12 | Humidity range of working environment | < 70% No condensation |

13 | working voltage | 220V,50/60Hz |

Samples:

How does laser engraving on marble works?

▼1. The CO2 laser works by emitting a focused beam of light that vaporizes the surface of the marble. With powerful laser beam and fast engrave speed etch

on the marble surface with complex designs,patterns,and text with ease.Unlike traditional engraving methods,CO2 laser engraving does not involve

any physical contact with the marble, decrease the risk of uneven or rough surfaces.

▼2. CO2 laser machine produces sharp, clean lines and flawless edges. Suitable for creating intricate designs, logos, and other highly detailed

artwork on marble surfaces. Additionally, the laser beam can also be adjusted to vary the depth of the engraving, making it possible to create

beautiful 3D patterns and effects on the surface of the marble.

▼3. CO2 laser engraving is also incredibly versatile and can be used on various types of marble, including white marble, black marble, and colored marble.

This means that it can be used to create a wide range of products, including plaques, awards, badges, memorials, and other decorative items.

Shipment and package

Certificate

FAQ:

Q. What types of laser is best for marble engraving?

A: CO2 laser engraver are regard as most suirable for marble engraving due to their ability to work well with stone materials.

Q: How do i avoid damage to the marble while engraving?

A: if you want avoid damage to the marble,first,you need to ensure proper laser setting,including low/medium/high power,and always perform a test run on

scrap material to fine-tune the focus and speed.

Q: Can you laser engrave any marble?

A: Yes, but results may vary based on the type of marble. Darker marbles generally show more contrast, while light-colored marbles might require coatings for black engravings.

Q: What is the difference between laser etching and laser engraving on marble?

A: Laser etching is a shallower process, making surface-level marks, while laser engraving penetrates deeper into the material, creating more pronounced designs.

Both can be used on marble, depending on the desired result.